Central Dust Collection System

- High-efficiency filtration, ultra-high-efficiency filtration efficiency, for powders with an average particle size of 0.5 micrometers, the filtration efficiency is as high as 99.99%.

- The cleaning effect is excellent. The dust collector is installed in a modular manner, which makes the construction convenient and simple, and it is also easy to clean the filter bags.

- The footprint is small. It uses a dedicated pulse-shaped pleated filter cartridge, with a compact structure that saves floor space.

- Installation is convenient. The filter cartridge is designed in an integrated manner, with excellent sealing performance, making it easy to install and replace.

- The operation and maintenance are simple. Users can choose to use the funnel-type bag filter or the cabinet-type bag filter according to the specific situation.

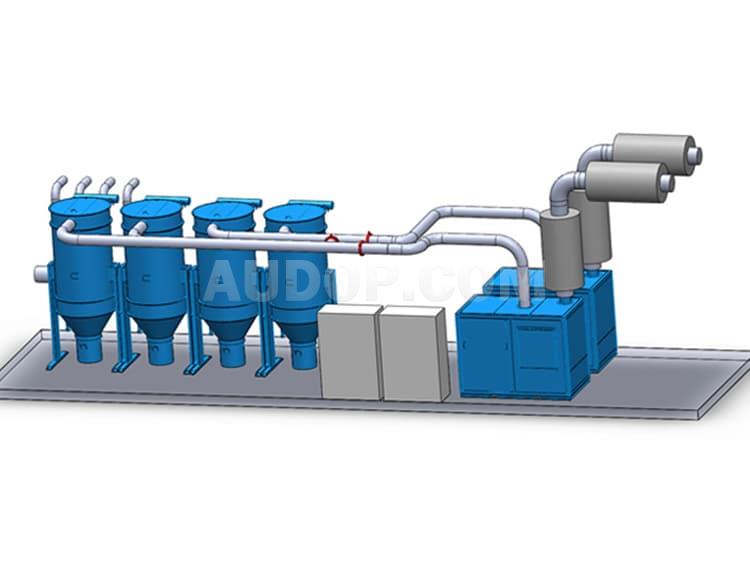

Overview

The industrial dust removal system is composed of components such as the dust collector main unit, dust removal pipelines, and fans. This dust removal system is suitable for dust purification and recovery in industries such as building materials, metallurgy, furniture, and hardware, with a wide range of applications, capable of performing either full or partial dust removal. The system is simple and convenient to operate, avoiding pollution caused by dust and ensuring a good working environment in the production workshop. It features high dust removal efficiency (dust removal rate ≥ 99.5%, with dust emission concentration meeting standards), wide adaptability, reduced secondary pollution, and easy maintenance.

Industrial dust removal equipment utilizes negative pressure fans as the power source. The strong adsorption force and rigorous filtration ensure excellent collection and discharge effects. From a safety perspective, industrial dust removal equipment can adsorb over 95% of dust particles, and collect certain flammable dusts into a safe sealed ash silo. To be on the safe side, a temperature-sensing fire protection system and automatic sprinkler alarm system are equipped in the ash silo, and the explosion-proof door is used in conjunction to ensure the safety of the workshop. From a health perspective, workers will naturally adsorb many inhalable particles during their work, which poses a great threat to the health of the on-site operators. Industrial dust removal equipment also adsorbs over 90% of inhalable particles, thereby ensuring the health of the workers and the working environment in the workshop.

Operating principle:

When the dust removal system is operating, the dust generated at the dust-emitting points in the production area is collected and sent to the settling tank through the suction pipe network. The coarse and heavy dust particles settle at the bottom of the settling tank, and are discharged into the dust transportation system by the conveying system; the light and fine dust enters the pulse bag filter dust removal device along with the air. This dust removal device uses high-density filtering materials to filter the dusty air, and at the same time, with the help of the online pulse blowing system, compressed air is sprayed in the reverse direction into the filter bags. Due to the expansion and vibration of the filter bags and the reverse airflow, the dust falls to the bottom, and is then discharged into the dust transportation system through the discharge system and sent to the subsequent processing steps.

Applied range:

Industrial dust removal is widely used in various industrial production processes for dust removal during polishing, cutting, grinding, crushing, combustion, and for effectively handling fine particulate matter such as debris, smoke, or dust. For example: in industries such as chemical, pharmaceutical, steel mills, power plants, carbon, abrasives, wood, smelting, mechanical processing, powder recovery, grain processing, pharmaceutical production, food production, powder transportation, plasma cutting, welding fumes, casting, etc.

Technical Parameters

Technical Parameters

This series of products are highly customized according to the customers' requirements. Therefore, we are unable to provide the procedures and parameters at present. If you are interested in this series of products, please contact us immediately. Audop Company will assign experienced engineers to communicate with you as soon as possible.

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Dust Collector Filter Bags

- Using dust-collecting bag filter material, the dust cannot penetrate the filter material. It is a surface filtration process. It starts as filtration and remains in the filtration state for a considerable period of time.

- The duration of the cleaning process is highly advantageous. It ensures that the filter material does not become clogged, and it does not alter the porosity or mass density. It can consistently operate at a low pressure loss.

- The coated filter material is a strong and soft fibrous structure with sufficient mechanical strength. It has descaling properties and reduces the cleaning force. Under low and stable pressure loss conditions, it can be used for a long time and extend the service life of the filter bags.

- Low pressure, high flow rate, continuous operation. Traditional deep filtration filter material.

- The dust removal bags are easy to clean and have a long service life.

Pulse Dust Collector

- The multi-chamber stop-air pulse jet cleaning technology is adopted, which overcomes the shortcomings of conventional pulse dust collectors and multi-chamber reverse-blowing dust collectors. It has strong cleaning ability, high dust removal efficiency, low emission concentration, low leakage rate, low energy consumption, low steel consumption, small floor area, stable and reliable operation, and good economic benefits. It is suitable for the purification of dust-containing gases and the recovery of materials in industries such as metallurgy, building materials, cement, machinery, chemical engineering, power, and light industry.

- Due to the use of staged air-stop pulse blowing for cleaning, a single blowing operation can achieve the goal of thorough cleaning. Therefore, the cleaning cycle is prolonged, reducing the cleaning energy consumption. The air consumption can be significantly reduced. At the same time, the fatigue degree of the filter bags and the pulse valves is also correspondingly decreased, thereby doubling the lifespan of the filter bags and valve plates.

- The bag replacement during maintenance can be carried out in separate chambers while the system's fan is not running and the system is operating normally. The bag openings are equipped with elastic expansion rings, ensuring good sealing performance and reliability. The filter bag ribs are in a multi-angled shape, which reduces the friction between the bag and the ribs, prolonging the bag's lifespan and facilitating bag removal.

- By using the top bag extraction method, during bag replacement, after removing the framework, the dirty bag is placed in the lower ash hopper of the box and then retrieved through the manhole, which improves the operational conditions for bag replacement.

- The box body is designed with an airtight structure, ensuring excellent sealing performance. The inspection door is made of high-quality sealing materials. During the manufacturing process, coal oil is used for leak detection, resulting in a very low air leakage rate.

- The inlet and outlet air ducts are arranged closely together, resulting in low air resistance.